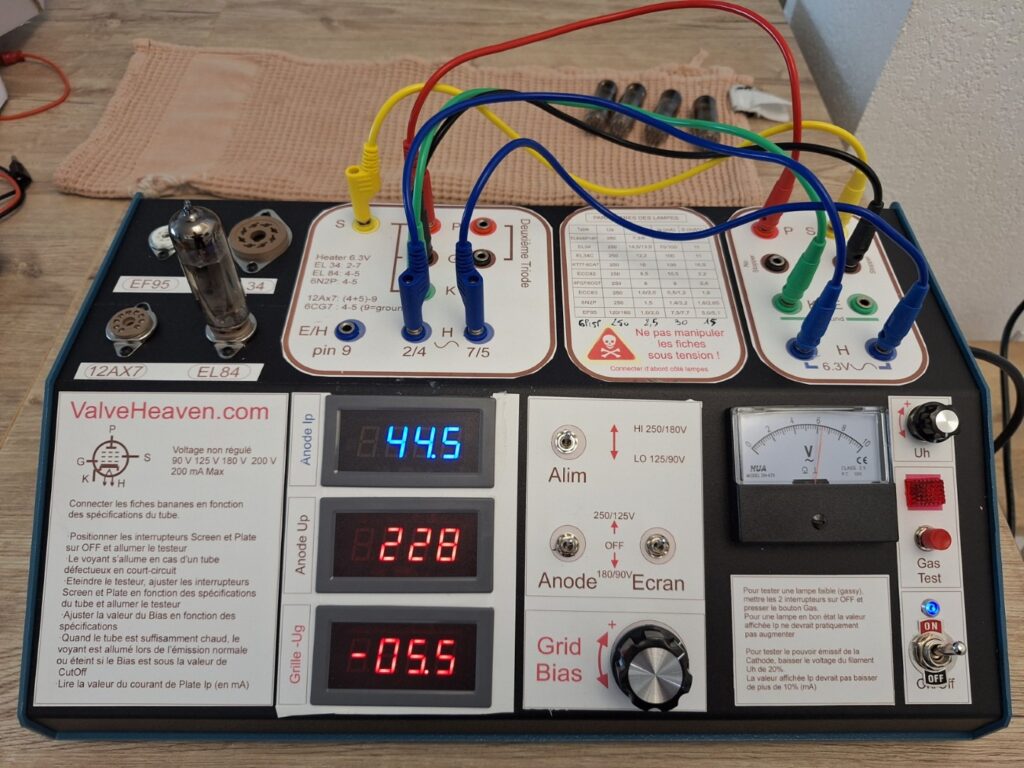

It has been encouraging to see that there has been quite a lot of interest in my valve tester design posted here some time ago.

I recently finished prototyping a much simpler design which is dedicated to testing the emission of 9 pin and octal power valves. In fact, it is so simple just about anyone could build it as it consists of only one transformer, three switches, three resistors, two valve sockets and an analog meter.

This tester will test a very wide range of power valves:

Octal: EL34, 6CA7, 6L6, KT66, KT88, 6V6, 6W6, 6CM5, 6DQ6, 6BQ6, EL36, 6F6, 6Y6, 7027, 5881, 6550…….

9 pin: EL84, EL86, EL82, EL83, EL81, 6M5, EL80, 6CW5, 6CK6, 6BQ5, 6CH6, 6BW6, 6P14P, 6P18P, 6P15P…… fortunately all of these valves share the same pinout for cathode and control grid which allows us to eliminate the switching that is normally required in a tester. Just plug in the valve and read the emission!

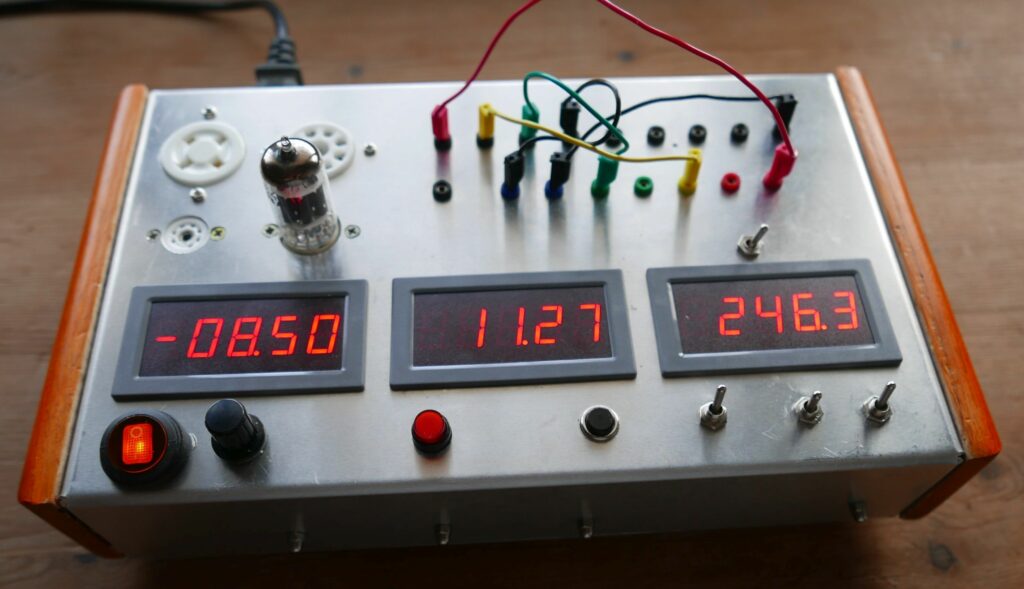

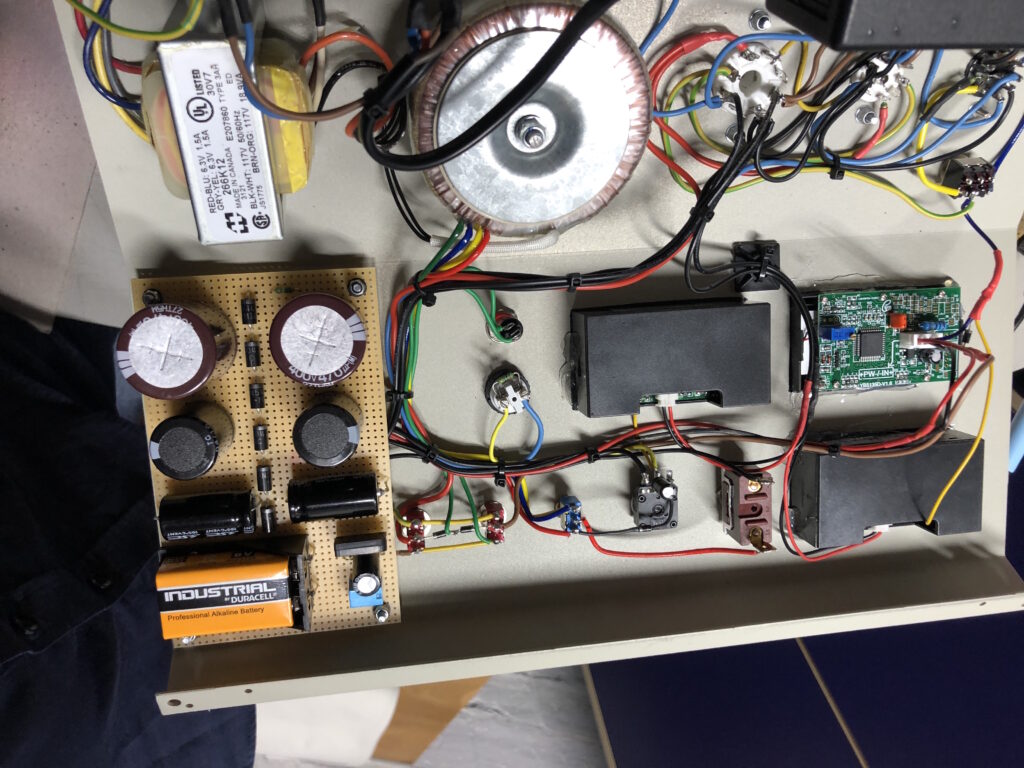

Here is the finished tester constructed in an old computer power supply case:

This tester provides a basic “emission” test – provides an indication of the capacity of the valve’s cathode to emit electrons. In much the same way that car tyres wear and eventually need replacing, a valve’s cathode eventually loses the capacity to emit electrons and the valve is “tired”. This tester provides an easy way to assess the condition of a valve – great for checking power valves that have seen a bit of life. It won’t allow for matching valves – you need a more comprehensive tester like my earlier unit to do this.

However, this simpler tester is ideal for a quick comparative test of the condition of your power valves. It works by applying a raw AC voltage between the cathode of the valve and the control grid which acts as an anode. The current that flows is measured by a moving coil meter and this indicates the condition of the valve. The amount of current is dependent on the valve type, however a comparison can be made with a known good valve to ascertain the condition of the valve that needs to be tested.

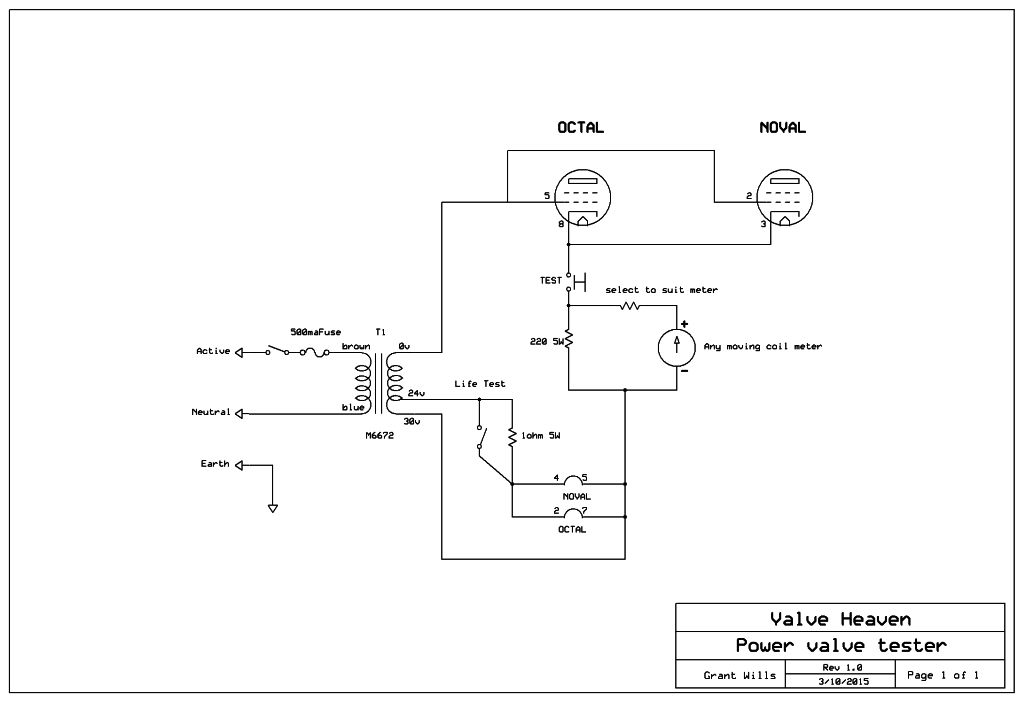

Here is the schematic of the tester – click on it for a larger image.

You can see how simple the tester works out to be in practice. A commonly available M6672 30V 1A transformer supplies the heater of the valve under test with 6V and the full 30V is applied to the grid of the valve which acts as the anode. The M6672 does not have a 6V tap, but by changing the arrangement of the transformer the 30V becomes 0V, the 24V tap becomes 6V and the 0V becomes 30V. For those in other countries, two transformers could be used – a 6V transformer for the heater and a 30V transformer for the higher voltage. A 220 ohm 5W resistor between the cathode and the other end of the 30V supply completes the test circuit. The valve effectively rectifies the applied ac voltage and develops a voltage across the 220 ohm resistor which is proportional to the current that flows through the valve.

A moving coil meter wired as a voltmeter with its series multiplier resistor measures this rectified voltage and provides a direct reading of the emission of the valve. Conveniently, the grid and cathode pins are common to a host of power valves, which eliminates the need for the switching which is normally needed in a valve tester.

One very useful feature of this tester is the “life test”. The life test switches a 1 ohm 5W resistor in series with the valve heater to reduce the voltage applied to the heater by about 1 volt. A valve that is low in emission can sometimes measure ok, but when the life test is switched in will show a significant drop in emission. A good valve will still read a good amount of emission even when its heater is underpowered by a volt.

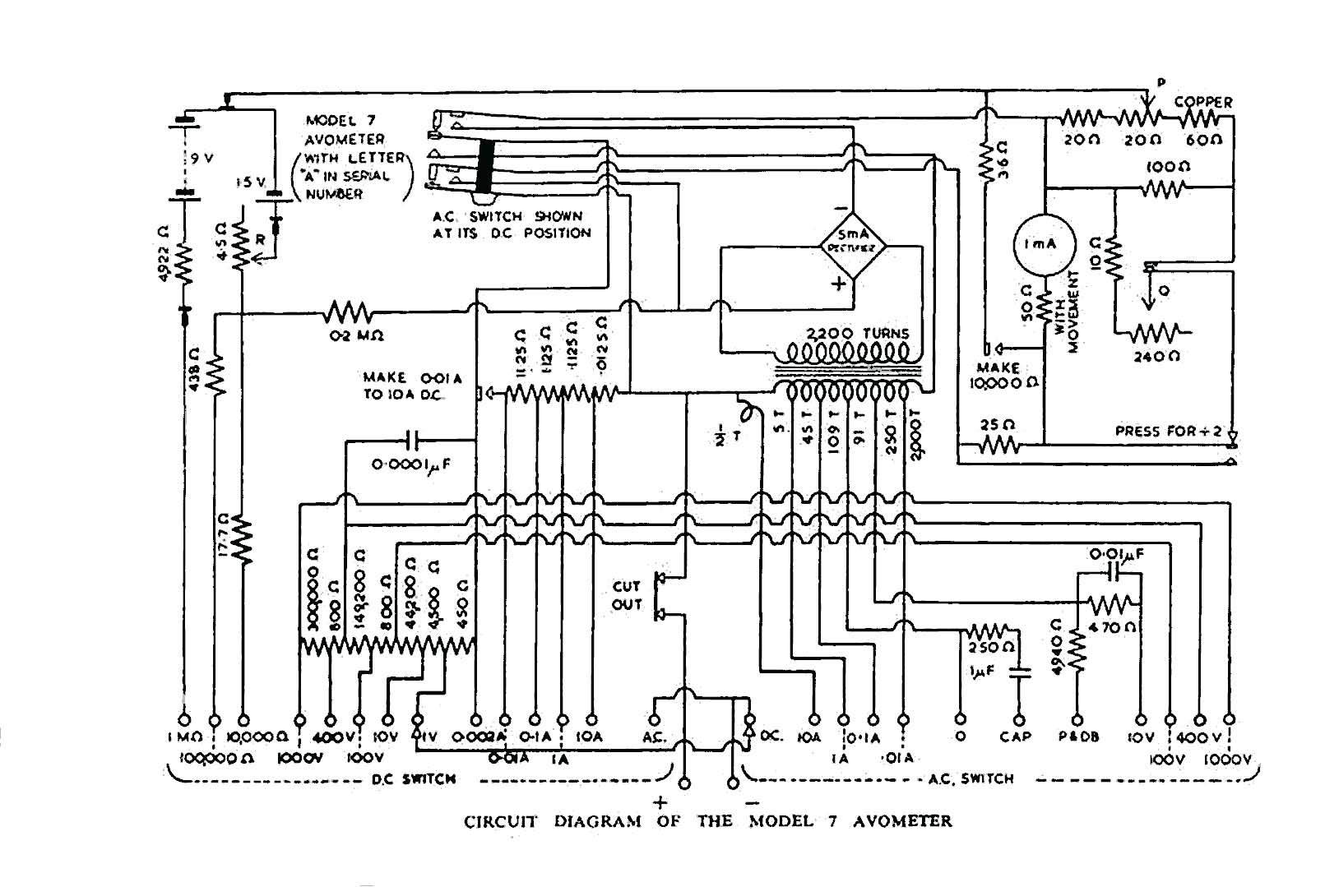

A note about the analog meter – an analog meter is preferred to a digital meter as it is easier to see the reading on a dedicated analog meter scale rather than having to remember numbers on a digital meter.You get an intuitive feel for how much meter deflection you expect to see with a particular valve. Just about any meter can be used from a 50uA to a 1mA movement. New meters are available cheaply from Jaycar and Altronics. You may be able to scrounge an old VU meter from a radiogram or tape recorder.

To use the meter of your choice, you just need to select a suitable multiplier resistor in series with the meter to read about 80% of full scale with a good valve being tested. I suggest you start with a 47K resistor and keep reducing the value of the resistor until you read the 80% of FSD with a known good valve. I used an old VU meter with the internal rectifiers and multiplier removed. This unit had a FSD of 80uA and the series resistor was around 22K.

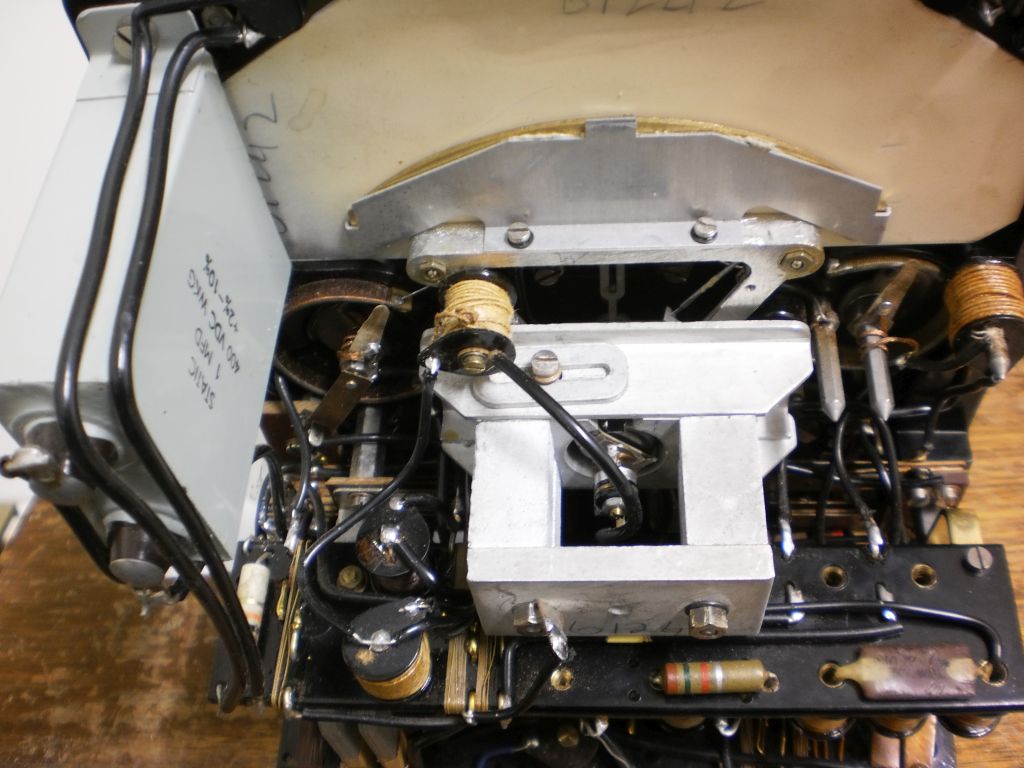

I used an old computer power supply case for the prototype, alternatively the tester could be built into the largest plastic “Jiffy” box from the usual stores.

A very useful tester and easy to build as well!

Cheers!