In addition to my passion for valve technology, a close second interest is Test Equipment. Over the years I have developed and built numbers of oscilloscopes, signal generators, valve testers, power supplies and many test meters designed to test a range of electronic components.

I was therefore excited recently to be given an old AVO multimeter made in England in January 1956. AVO meters have a long history going back to 1923 when the original designer came up with a design to combine an Ammeter, Voltmeter and Ohmmeter in one unit – the “AVO”. They have been regarded as the “Rolls-Royce” of multimeters and until recently I had never owned or used one in the flesh. They are built like a tank and have a precision unlike most analog meters – within 1% on DC ranges.

This particular AVO was a model 7 mkII version with the code A156 marked on the meter scale indicating it was made in January 1956. It was in particularly poor condition when it was given to me. Several of the DC and AC voltage ranges were not working, and the meter movement was sticking and was reading low. To start the restoration, I spent some time cleaning the very dirty front panel and case with a toothbrush and mild detergent. After several applications of this treatment, the 60 year old grime was removed revealing the original black bakelite front panel.

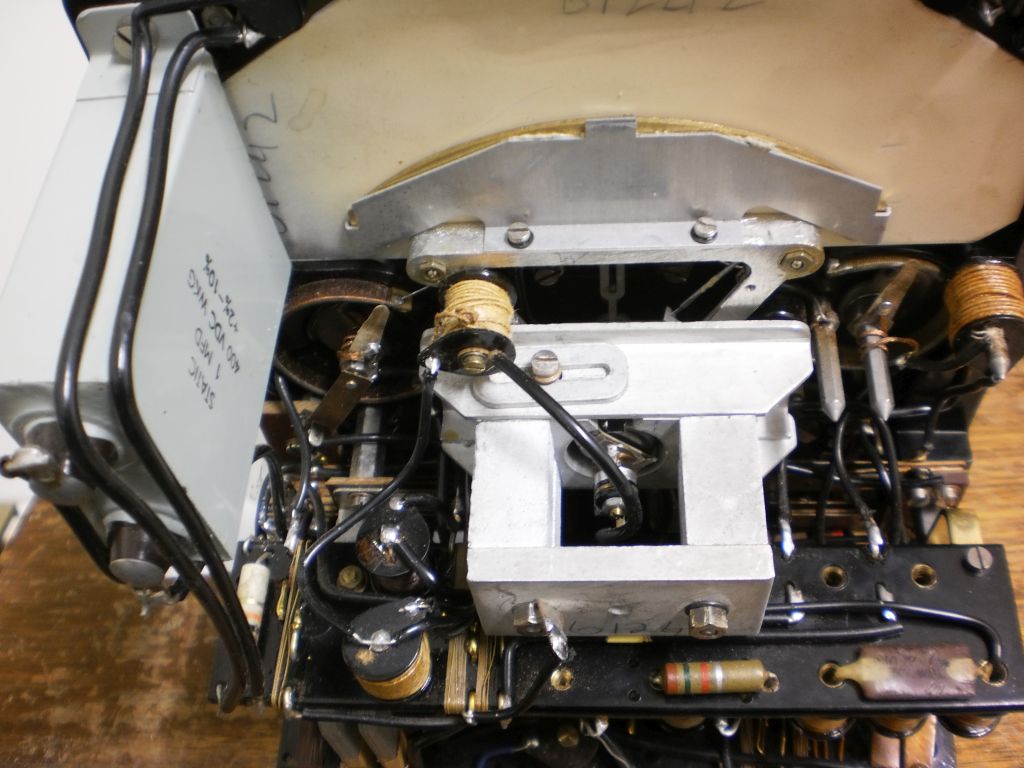

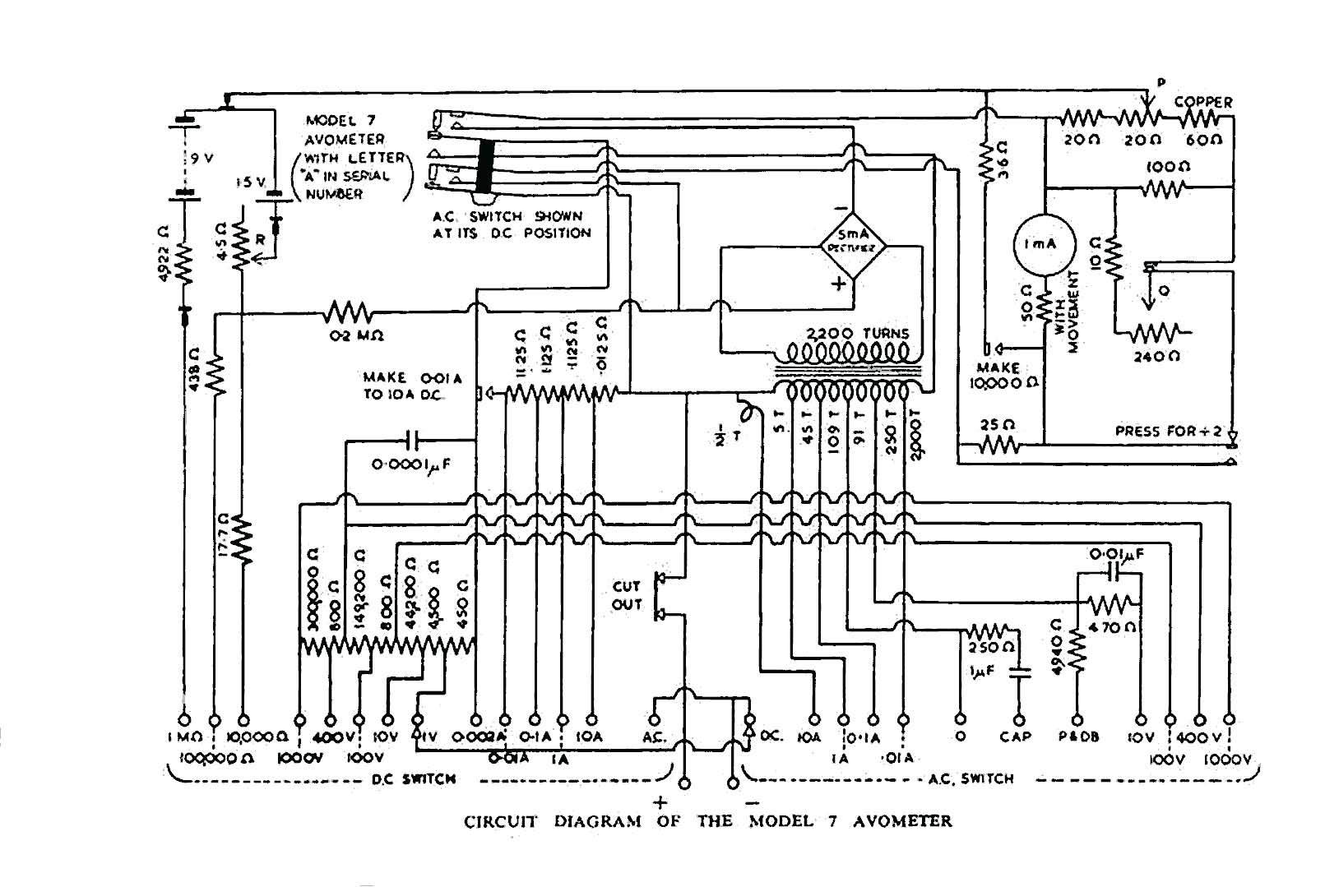

I then set to work on the mechanical and electrical issues with the AVO. First I wanted to know why the voltage ranges were not working. The different ranges in a voltmeter are arranged by adding series resistance to the meter movement – called multiplier resistors. My guess was that one of these multiplier resistors was open circuit and so it turned out to be.

On the lower left of the circuit you can see the multiplier resistors in series. The 4500 ohm resistor was open circuit. These resistors are precision wirewound to a tolerance of .3% and hand made. I attempted to repair the resistor but it was broken internally, so I wired in place a parallel combination of 2 resistors selected for exactly 4.5K ohm.

Having repaired the multiplier, all ranges were checked and found working. However, the meter was reading low and was sticking at about 2/3 deflection. Taking extra care, I removed the meter movement. It is a substantial affair with large alnico magnets. Sticking in a meter is often due to very small magnetic filings lodged in the gap between the movement coil and the meter magnet. Carefully I found some particles and removed them which freed the movement. A small adjustment to the meter magnetic shunt completed the repair.

The AVO was now restored to full working condition. While its performance can be matched with cheap digital multimeters these days, it was a lot of fun restoring it and maybe my amp designs will have a bit more mojo and vintage tone if the AVO is used in developing them 🙂