For quite some time I have been looking at developing a design for a diy valve/tube tester that is easy to build and uses readily available, low cost parts. A valve tester is an invaluable tool for those who wish to build and repair valve amplifiers.

Old vintage valve testers are available online, but most of them provide only a crude “go/no-go” result. They also fetch ridiculous prices for such simple tests. What is really needed is a tester that will measure a valve at true operating conditions.

In looking at a new valve tester design, I wanted it to provide these features:

1. Provide emission readings at the recommended databook operating conditions (Plate, Screen and Grid voltages)

2. Provide Gm or mutual conductance readings, directly or indirectly

3. Test valves for internal shorts

4. Test for “gassy” valves – valves whose internal vacuum has been compromised

5. Test a wide range of valves, from 12AX7s to KT88s and any other “receiving” class of valve

6. Be expandable with options to include heater/cathode leakage testing, other valve bases, different heater voltages, “life test” etc

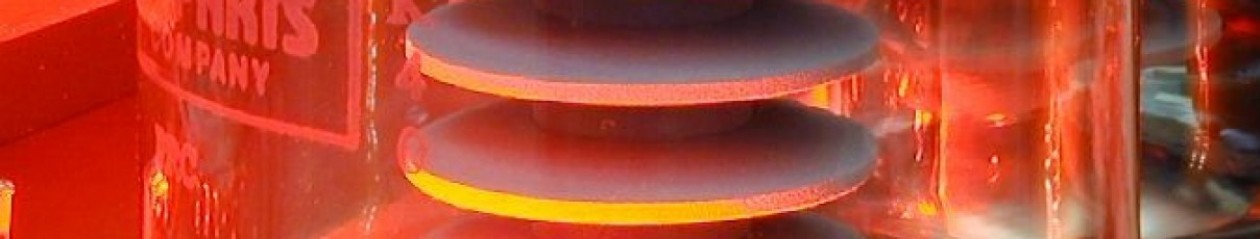

I have recently completed the following tester design which does a great job of testing any valve/tube in the “receiving” class. Unlike the old “emission” testers of the past, this low cost tester provides a true test of a valve at valve databook conditions. In addition, it tests for shorts and “gassy” valves with the ability to measure the Gm or transconductance of a valve. It uses low cost, readily available parts and can be built for well under A$100.

Full design and constructional details can be downloaded by clicking on this link:

An inexpensive, easy to build diy valve tester

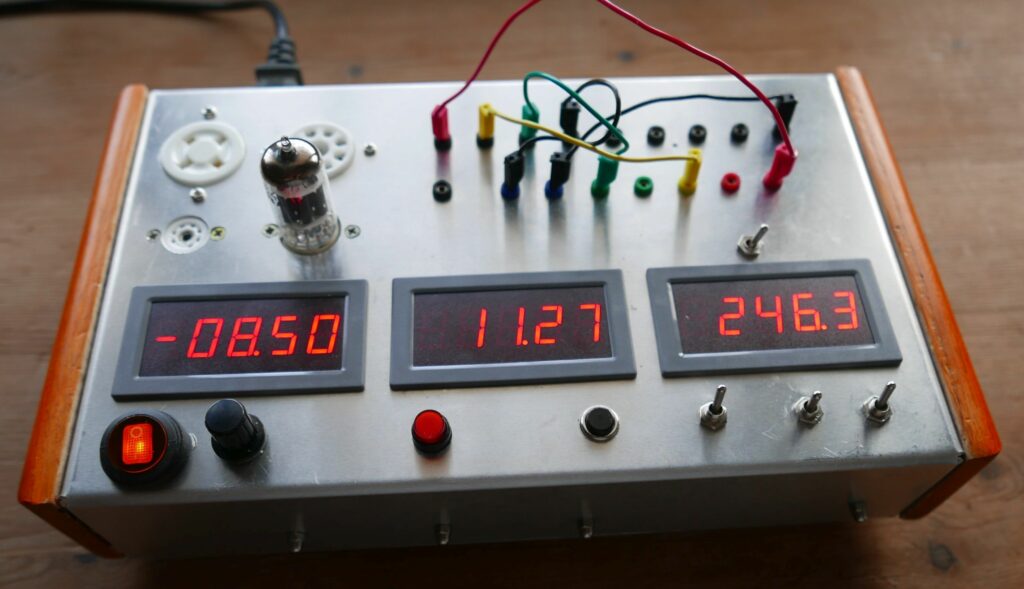

Here is the completed unit testing a KT88 valve:

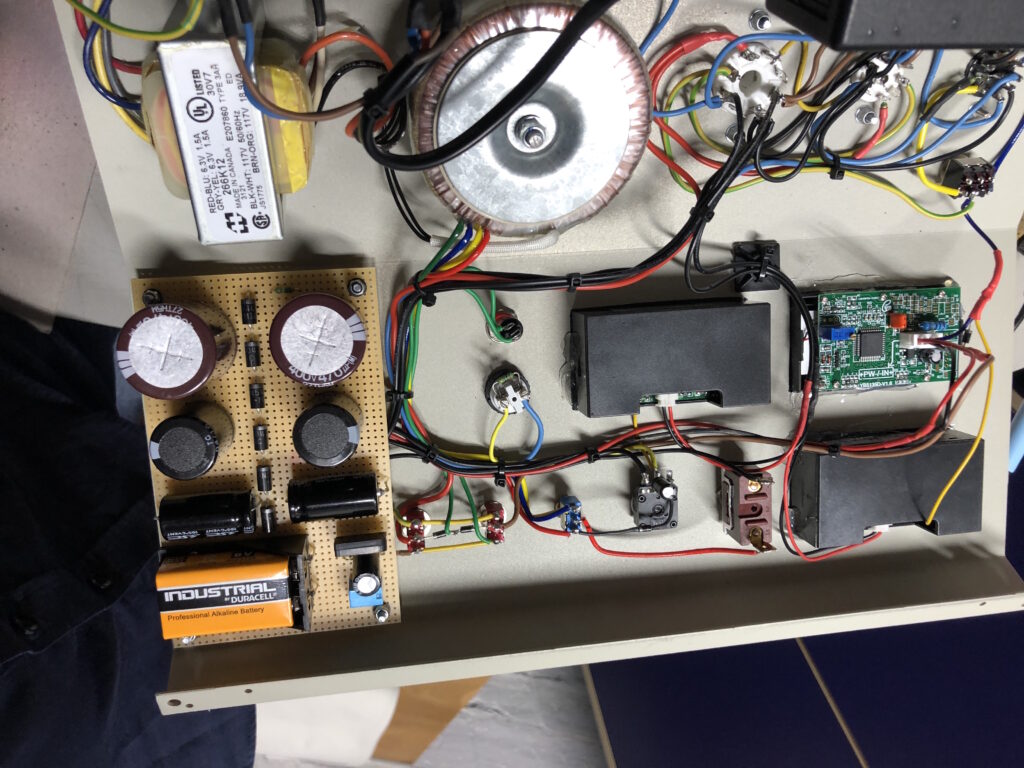

8/5/2019 Some photos of another finished tester from Rob in the UK

And another successful build from Johan:

And another build by Chang

And a recent build by Adrian Langford

Hi Grant I am looking to build this project and after looking at your PDF instructions seem to be a bit confused with the back of the power board wiring.. There seems to be 3 resistors that are located on the board but not listed on the schematic or have I miss read something here. Thanks for the post of this tester and hope to complete soon…

Thanks Wayne for your interest in my valve tester design. Yes, the photo of the prototype power board shows 3 bleeder resistors, but the single 150K resistor as shown in the schematic will do the job fine!

Hi Grant I have started the build on the valve tester. Just trying to clarify the use of the DPDT TOGGLE switch listed in your build shopping list. From the photos of the build it looks as though this switch has been used to tap the two HI/LO taps from the transformer and also an additional supply to the bias supply via D2. Would this be correct? Adding further to this, is the DPDT switch be bridged across each pole to effectively use as a bigger SPST switch. Just trying to work out what looks to be solder on those lugs from your supplied photos. Thanks once again.

Hi Wayne,

Great to hear you are progressing with your build. Yes, I wired both sections of the DPDT switch in parallel to increase its current rating.

The bias supply is permanently wired across the full 30V winding.

Cheers!

Thank you Grant post this useful post. Nice !

I just build my own in Aug, 2024.

HI there 🙂 I am interested in building this handy tube tester of yours but I am a little confuse with the switch in the picture and in the schematic,In the full version of your schematic it looks like the Screen voltage and Plate voltage are using DPDT switch and the HI /LO switch is a SPDT correct?. In the picture it looks like you have either 2 HI/ LO SPDT or an independent Screen and Plate voltage control. Would you kindly guide me through? 😀 I’m 16 and I have a passion for tube amps 😀

Hi Ben,

Thanks for your enquiry.

The plate and screen switches are SPDT centre off switches. The hi/lo switch is a SPDT switch. In the prototype I used a DPDT switch wired with both sections in parallel.

Hope this helps and all the best with your interest in valves!

Hey Grant.

Very awesome project. Ordered my parts. Had to change a few things here and there, only because South African Electronics stores don’t always carry the stuff I need – only separate transformers for supply and heaters. What I actually wanted to ask is I see there is a resistor next to the Neon lamp on the schematic with no designator or value. Is it needed?

Regards

Hi Nicholas, great to hear you are building my tester. The neon is shown with a series resistor as a complete 240V neon assembly. When you purchase a 240V neon “lamp” it has the resistor built in. Of course if you are using just a neon bulb, you need to add a resistor of approx 220K in series. Hope that helps!

Interesting project.

In my ´transformer bin´ I have an old PT110. Primary 230V secondary 6V3 and some 265V. Please help me how to convert the secondary 265VAC to the required voltages 90/125/180/250VDC. A simple transistor in a resistance divider would not suffice I think because of the high CE voltages involved. But maybe you have a simple solution?

Hi Arjen,

Thanks for your interest in my valve tester project. Unfortunately a standard high voltage transformer does not allow for the different voltages required for a tester. My tester which uses a low cost low voltage transformer and voltage multipliers provides the voltages required with easily sourced parts. Cheers.

Hi Grant. First thanks for making available such a great design. Will build this probably on a PCB as I will use a smaller enclosure. You say other tube sockets can be used of the receiver type. Could you explain a bit more. I never use 7 pin but lots of the other two and 300B, 2A3. Can this be done? With probably more grunt in the PSU particularly for the 2.5V 2A3’s.

regards Dave

Hi Dave,

Great to hear from you. My tester was developed for indirectly heated valves and could be expanded with say UX4, UX5, UX7, loctal, etc sockets depending on the type of valves being tested. As it stands, it was not developed with directly heated valves like 2A3 and 300B in mind, but in theory the tester could be adapted by using different taps on the M6674 to provide the different heater voltage for these valves. If you have success modding the design for directly heated valves, let us know!

Thanks Grant,

1. Had a look and a big think. Simplest way to add most 4 pin DHT tubes to your design is to just suck it in and buy another transformer. The Hammond 266M5 will do but VT4C has one at USD15 +post much cheaper.

2. For the displays I understand cost was the design mantra. I will use 2 DC DC isolated converters and LCD displays from China – 20ma each no big design deal. The DC converters are about the price of two good batteries. And must admit I hate batteries as they seem to die just when you need them.

3. Just another point of view I guess which I hope helps.

4. As would getting this Project to the PCB stage. Used to make my own PCB’s but now firms in China deliver a quality product cheaper than I can do. And they deliver 5 boards as the minimum order for less cost to build my one..

5. So Grant gets a freebie of course. I already have 2 more interested. With Grant’s OK anyone else interested ?

regards Dave

Thanks Dave for your thoughts. Would be great to see the design expanded to test DHTs. Keep us posted on your build!

Hi Dave,

If you still have the PCB available, I would be very interested. Happy to pay postage etc. Regards John.

Did you ever finish the PCB? I’m interested in something that will test Direct Heated Triodes. I work on old jukeboxes that use 30’s and 45’s . I also use 300B’s. Old tube testers are going for ridiculous money. I’d rather build something I can get parts for.

Hi Dave, I am interested.

Hello, very nice your tube tester.-

I want to, but I have to ask you a question:

Banana sockets : 7

P : Plate (anode)

S: Screen (g2)

G: Grid (g1)

H: heater

H: heater

K: cathode (k)

E: ??????? —– For what electrode is?

I await your response

Thanks

Best regards

Hi Gus,

Great to hear you are planning to build my tester.

To explain, the E socket is wired to ground and is useful for testing certain valves. For example, for connecting grid 3 of an EL34 to ground, or for supplying heater power to a 12AX7 by connecting pin 4 of a 12AX7 to “E” ground so that pin 5 can be grounded to heater ground and pin 9 connected to heater 6.3V.

Hope this helps!

Grant

Grant, thank´s for answer.-

Another question:

In the part list : D1-D4, D11 are 1N4007, but in the circuit diagram D11 is 1N5404, so wich is right ?

I await your response

Best Regards

Gus

Hi Gus,

Yes the circuit shows D11 as a 1N5404 but you can use 1N4007 also.

Cheers

Hi Grant.

Share your love of valves so as said earlier here now working on a version to include the valves I use. Yup I know very selfish but let’s face it. Why build something you don’t use. Your great design as the basis pretty much intact. Would have taken a while.

Don’t know how to post layouts here. If there is a way will share.

regards

Dave

Nice project… I’ve managed to source most of the parts, but I’m in the US which makes the transformer a bit of a puzzle. I could conceivably use a clothes dryer outlet to power the 240v transformer, but the M6674 doesn’t seem to be available in the states and shipping one here drives the cost up quite a bit. Far better would be a transformer with a 120v primary, but I’m just not having any luck finding a suitable substitute… just curious if anyone else has had any luck finding the right transformer.

Hi, great to hear of your plans. Re a power transformer for the USA, you can substitute the M6674 with two transformers – one 120V to 6V 2A and the other 120V to 30V 2A centre-tapped (ie 15V-0-15V). Both are available from ebay or Mouser etc. Happy building!

Hi Grant,

I’d love to build this tester. I’m in the USA. Can you go into a little more detail on how you would change the schematic for the two transformers (120V to 6V, and 120V to 30V) you suggested?

Hi John, I’ve posted some details earlier in this thread. Cheers.

Yeah, that was what I was thinking, but I wasn’t sure what amp capacity I would need.

I think I will dispense with the opticoupler part of the circuit. Instead I think I’ll build the tester inside a suitcase type of box with room to store a pair of bias probes and a pair of multi-meters that do double duty. I can just grab the kit to match tubes and bias an amp.

Hi Grant,

I’m looking to build the tester and looking at a solution for the heater supplies. Will it be possible to draw the heater supply from the top half of the 15V AC winding? (assuming the bottom end of the winding is grounded). I am looking at using at 30VAC center tap transformer of 80VA rating? Am planning to use a regulated DC for the heaters either via 78xx or LM317. Appreciate your input. TIA..

Hi David,

Great to hear of your plans for the valve tester. Re using a 15-0-15 transformer and supplying the heater from the 15V winding, it could be done, but is very wasteful of power and would result in large dissipation (read heat!) in any dropping regulator etc. For example, if you were testing an EL34 with its 1.5A heater requirement, the regulator would be dissipating around 18W of power with attendant heat problems. I’d suggest that you chase up a separate 6V 2A transformer – simpler and easier to wire up and no heat issues.

Hi Grant,

Thank you for your response. In other words what you are suggesting is just going for an AC heater supply instead of DC regulated supply. In order for me to test valves having 12.6V filaments, i would need to get a dual secondary 6V transformer. The problem i am facing where i am is the AC supply is about 240-245VAC. Transformers i am able to purchase are 230VAC. Usually there’s a 20% increase on the supply on the secondary windings. I would need to get the supply adjusted down to either 6.3 or 12.6. Using a series resistor to drop the voltage down is one way, but wouldn’t this vary for different valve filaments? Do you have a better way of implementing this?

thanks,

David

Hi David,

Re your concern about mains voltage variation, I wouldn’t be too concerned about it. As long as the heater voltage is within say 15%, you should be fine.

Cheers.

Thanks Grant…Cheers

Hi Grant,

Great DIY project just what I need. I am having difficultly in locating a transformer M6674 some searches come back with M6674 L I live in the UK and this transformer does no show up here. Tried a search for a 240v/30v 2a center tapped transformer but cannot find this type in the UK either any thoughts would be great as I would really like to build the tester.

Thanks

Dave

Hi Dave,

There are several ways to provide the AC voltages required for the tester. I suggest looking for two 240V to 15V 2A transformers if you can’t find a 30V 2A. Ebay is your friend here 🙂

Hi Grant,

I located 240v/30v 2a center tapped transformer. You mentioned getting a 6V 2A transformer for the heater supply. How is this used as in the schematic this taken from the 24v tap of the M6674. Not sure how that comes out at 6.3 volts.

Thanks

Dave

Hi David, just connect one side of the 6V winding to the bottom of the 30V winding as per my schematic and connect the other side of the 6V winding to the heaters. Cheers

Hi Grant,

a couple of quick questions: The M6674 transformer seems to be discontinued at Altronics. Jaycar have the MM2005 30V 2A multi tap transformer, with 15v as the centre tap. Can you suggest if this is a suitable replacement? And secondly, having trouble sourcing 470uf 350v caps…any ideas here? Thanks.

Hi John,

Yes, the MM2005 is an equivalent of the M6674 so is interchangeable. 470uf 350V caps are available from Altronics in Australia. Cheers!

Hi Grant,

Planning to build the tester but can’t find the 470uf 350v caps anywhere. Jaycar haven’t got them and I can’t find them online.

Any pointers?

Cheers

Rohan

Hi Rohan,

470uf 450V capas are available from Altronics. Cheers.

Hi Grant,

I’m also planning to build this valve tester, have gathered most of the parts except the capacitors. I did have some questions but reading through the previous posts they have been answered!

Thanks for your work.

Cheers Keith.

Great Keith!

Hi Grant, first off I would like to say that your plans have been very helpful in helping me understand how to test tubes.

I have been working through your schematic to understand how it works before I just start throwing parts together. I plan on building the MKII with the banana plugs and such. So far I understand why your are using the seven banana sockets and understand that P = plate, S = Screen, G = Grid, etc but the only one I don’t get is the E = ?. Could you please explain to me a little further as to where and/or how that would be used? I was comparing both schematics for the MKI and MKII but I’m lost as to what the E would be used for in the second design. If it’s one of those things where it would take to much time to explain, could you please point me in the direction of what I should study? I am just beginning to learn about tubes but I have a strong background in audio and electronics. Any help will be greatly appreciated!!! Thanks.

Hi Richard,

Great – you found the reason for including the E plug.

Happy building!

I probably should have read through all the comments first because that is where you already answered my question…..duh. Anyways you have a GREAT site here, very informative and helpful.

Thanks Richard!

Hi again Grant, this maybe another noob question but here goes. You said in your write up that you could measure Gm indirectly by varying the grid voltage by 1 volt and measure the change in plate current. Could you please explain to me the formula you use to get a Gm measurement in umhos?

Hi Richard, Gm is a measure of the change in plate current for a change in grid voltage. Typically so many mA of change in plate current for a 1V change in grid voltage – mA per volt also referred to as milli-mhos. To convert to umhos (micromhos) just multiply this figure by 1000.

Hope this helps! Grant

Thanks Grant!!! That helps quite a bit…I was wondering how everybody was getting such large figures. Thanks to you and several other online resources, I believe that now I’m finally getting a grasp on how it all works: tubes, amps, testers, etc.

I think I am going to use your basic design and try to incorporate that into an Arduino with a 16×2 Lcd. I know I will be able to get it to measure the grid volts properly but getting the proper resolution for the mA might prove to be beyond the abilities of the standard Arduino (I’m trying to be cheap and not buy anymore extra parts 🙂

Anyway thanks again for you help and all the info!!!!

Hi Grant, thanks for publishing your design for such a fantastic basic tube tester. My audio system uses tubes in all amplifiers, and the DAC output, and my Monos are OTL’s which have 16 output tubes each,…so being able to test and match tubes is paramount for me. A simple query if I may, have looked at the readings for the 3 tubes you tested and published, 6V6, KT88 and a 12AX7. I whipped out my performance sheets for the 12AX7 (RCA) and your result matchs fairly well with RCA’s data using a Plate V of 250V, and indicates that triode half is good as new. But the KT88,….well I then pulled a performance sheet from Svetlana and their sheet has data for “Vscreen of 300V”, “Vscreen of 140V”, “Triode Connection”, and finally “UltraLinear Connection”. OK, so I’m guessing that I should be referring to one of the first 2 graphs, but the tester cannot supply Vscreen voltages for either. Could you please help me apply your results to a know KT88 graph so I can then interpret my own results against other tube graphs when I start testing tubes with this tester, I’m about half way thru my build. Cheers, Mark.

Hi Mark,

Thanks for your kind comments and background to your build.

Re the KT88 or any other valve, I would suggest you do some web searching for several datasheets. I found this Genalex datasheet at National Valve Museum http://www.r-type.org/pdfs/kt88.pdf and it refers to tetrode data of 250V anode and screen which suit the voltages available from my tester.

Cheers, Grant

Grant, really nice concept and design, it’s not easy making something that works AND simple!!!

That being said, I’m a Yank, and that tranny won’t work easily for us… What do you suggest, a 30V CT and a 6.3v heater tranny’s?

A quick look through ebay, and I saw some dual display panel meters, DC Volt/Amp… Not sure of teh range, but that might be teh ticket…

CR

Hi Chris,

Good to hear from you.

Yes, numbers of my tester have been built in the US with substituted power transformers. You can find them on ebay or Mouser – you need a 120V to 6V 2A and a 120V to 30V centretapped at 2A.

The ebay panel meters could be used, but be aware of how they reference the ground – ie the common input will be typically tied to the power leads. If they are used, you will need to power them from an isolated power source. That is why I used isolated DMMs for the meters in the prototype.

Have fun!

Hi Grant,

Love your project so much that I have already printed a dozen copies of the pfd. Still, I ask myself, how does your baby compares to the sussex tube tester?

Cheers,

David

Hi David, thanks for your comments. Re my tester vs the Sussex tester, my design is quite a lot simpler. The Sussex tester allows you to select a wide range of plate and screen voltages, while mine simplifies this to a lower number of test voltages that are those commonly used in valve data sheets. This simplifies the power supply considerably, while still providing usable measurements at data sheet settings. Cheers!

I greatly appreciate your circuit since it is most necessary for the tube guru on a budget.

However, I have a question that I hope you can resolve.

Viewing the basic schematic, four toggle type switches are present as noted below:

Hi/Lo on the sec of the xfmr (SPDT)

Screen Volts (SPDT)

Plate Volts (SPDT)

12AX7 sec1 & sec2 (SPDT)

Why does your pictures and parts list show a DPDT switch, is only 1 section used?

In the event the latter is the case, can I use another SPDT to replace the DPDT.

Please identify/clarify where the switches are regarding the schematic in reference to the pics.

The above is not written out of any disrespect, I am puzzled…

Thank you!

Sorry, for my previous question – I noted the info within the thread.

Thank you for the excellent circuit, it is very thoughtful of you to present this circuit to us.

I have noticed a few testers that have an audio IN/OUT RCA phono jack for actually listening to the amplification through the preamp tube test; would it be possible to place a circuit in your project to provide the latter?

Hi Frank,

Thank you for your encouragement and good to hear you found your answer in the previous comments.

Re using the tester to check for noise and sound, I haven’t done this but in theory it would be possible. You would need to inject audio into the grid and put a transformer in the plate lead to couple audio out.

Cheers!

Hi Grant.

Beautiful project especially for the availability of the components used.

I’m trying to make it happen and in the meantime I have collected almost all the parts except for the transformer I’m doing … and built specifically to test other valves 2a3 and 300B kind I added another processor only for these tensions ….

tThe My question is this ….. starting to assemble pending the transformer, I did not understand at best, even reading it tread, connecting 2 spdt and dpdt, it would be possible for her to post a more detailed picture of the various connections or mark with “s1”, “s2” etc .. the location of the switches in the wiring diagram ??

Thank you

Tony

Hi Tony,

Great to hear you are building my valve tester. Re the switches, I used a double pole switch for the HI/LO function with both sections in parallel. The other two switches are single pole.

I’m interested to buil this tester thats seems very simple but i’m in doubt about DVM’s conectiion.

I didn’t understand the connection of batteries Could you be a little bit more clear about? If possible send a photo showing the conncetions.

Tks

Hi Paulo, good to hear you are planning to build the tester.

Re battery connections, just disconnect the positive battery lead and wire it to the opto isolator as shown in the schematic. The other side of the opto connects to the lead you have removed from the positive terminal.

Hi Grant,

I’m planning to build the realy nice tester you’ve developped. I’ve one question about the banana sockets. In the schematic I see 7 banana sockets, but on the pictures of the tester I see only 6 banana sockets. Why is that?

Greetings,

Adrie

Hi Adrie, the extra terminal is used for a valve needing an extra ground like a suppressor grid, or a twin triode needing a different heater arrangement. In my prototype, I added the extra ground banana socket at the rear of the chassis to make a total of 7 sockets. Regards, Grant

hi i came accross your valve tester last week and now have most of it built but ive installed valve bases and rotary switches to ref pins also fitted banana jacks to input higher heater voltages and oddball bases have used seperate trans for heaters to give a wide range of voltages but havent got 15/0/15 trans but have many 18/0/18 ones this gives me 105/145/210/265 after the maltiplier ive not done much with malltiplier circuits can it be altered to acheve different set of voltages?thanks phill

Hi Phill, great to hear you are building the valve tester. A 18-0-18 transformer would work in my tester with the proviso that as you say the HT voltages would be increased by 20%. You would need to take that into consideration when testing valves.

can i use a tap off one diode below and use the 87v ? and would i need it , i want to test the valves from a 90 volt battery set with 2 volt heaters , among others , phill

its phill again ref c3 47uf 63v it apears to be upside down is there a reason for this.phill

ok i see its – volt line fotr the grid got it

Hi Grant,

Thanks for this great, long-sought-after (for me) project! It finally puts quality Gm tube testing within my reach. I’ve never been able to afford a quality tube tester.

I’ve looked for the past few hours online, and read through these comments, and I am having a really hard time finding transformer(s) for this project. You mention Mouser or ebay for sourcing an M6674/MM2005 equivalent, as both those are apparently discontinued. I can’t even seem to find 120v to 6v 2a or 120v to 30v 2a center tapped transformers anywhere – most of what I’m finding are the right voltage, but much lower amperage than that. Would you mind looking up some examples on ebay or Mouser and providing me with some actual part numbers for transformers that are actually in stock and not discontinued? It would really help me out a lot. I’m sorry to sound like such a noob with this, but I just cannot seem to locate the key parts for this project and I really want to get going. Thanks again for all you do!!!

Hi Jason, your best bet is to check out Ebay and other online sellers. I assume you are in the US and a quick look on Ebay.com found this: http://www.ebay.com/itm/JAMECO-SHIELDED-POWER-TRANSFORMER-115V-TO-12-6V-center-tap-6-3V-2A-/272229927928?hash=item3f622b0bf8:g:zqwAAOSwFEFXJlgP

And this: http://www.ebay.com/itm/32VCT-32V-16V-Transformer-16V-0-16V-CT-2A-110Vac-220Vac-to-32Vac-16Vac-free-shi-/272031999836?hash=item3f565ee75c:g:TdoAAOSwwbdWM9q1

Grant

Hi, looking to build your tester, BUT not able to get the Transformer in the UK at a fair price, jacar want £28 just for shipping,, could you please tell me if there is any way that i could use the cheepo bench PSU’s that are rated at 30V 5A adjustable voltage cheers and thanks Shawn

Hi Shawn, thanks for your interest in my tester. The 30V supplies that you refer to are DC and not AC and are unsuitable. I suggest you read all of the comments on this project – there are several options that I suggest for builders outside Aust. Cheers!

Hi, one little doubt the transformer its multi secondary transformer , with 30V , 24V, 15V like in the schematic. Thanks

Hi Pedro, yes the power transformer is a multitap transformer. See here: https://www.jaycar.com.au/9-30v-60va-2a-multi-tapped-type-2165-transformer/p/MM2005

Hi Grant

I’m in Trinidad in the Caribbean and currently building your valve tester.

Here are some part numbers and links to the components I’ve sourced for it (115vac 60Hz). Will update the group on the build in due course.

Hope this may help someone.

Cheers, Cletus

Mouser

647-UPT2D471MRD UPT2D471MRD 200volts 470uF

661-EKMQ351N471MA30S EKMQ351VSN471MA30S 470uF 350 Volt

Jameco

29226 TRANS,PWR,12.6VCT/2A,115V/AC, WIRE LEADS

21979 SWITCH,TOG,MIN,DPDT,ON-ON SOLDER,120V/5A,1/4″MTNG.

21952 SWITCH,TOG,MINI,DPDT,ON-OFF-ON 5A@120 &2A@250VAC,1/4″MTG

36011 DIODE,SIL REC,1N4007,1A, 1000V PRV (10)

36265 DIODE,SIL REC,1N5404,3A, 400V PRV (10)

2231961 INDICATOR,NEON PANEL,RED,115V, RNDw/DOMED TOP,4.5″LDS,.50″H

40985 OPTO,4N25,NPN TRANS,2500Viso, 1.2Vf@10mA,30Vb

2246320 POT,LINEAR TAPER,10K,1/8W,20%,16MM,.235″KNURL SFT,PCB TERM

26649 SWITCH,PB,MINI,SPST,ON-(OFF) CHROME,125V/3A,.299″MTG,EYE LUG

120994 FUSEHOLDER,PANEL MOUNT,NON UL .25″X1.25″FUSE,SOLDER TERM 2D

Ebay

https://vod.ebay.com/vod/FetchOrderDetails?itemid=272031999836&transid=1933223240017&ul_noapp=true

Tube Depot

https://tubedepot.com/

8 Pin Octal Socket Drop in Suitable For Fender® Brand Amplifiers

7 Pin Chassis Mount Socket with Solder Tabs

9 Pin Miniature Plastic Chassis Mount Suitable For Fender® Brand Preamps

Hi Cletus, good to hear of your valve tester build and thanks for the links to substitute power transformers and other parts. Cheers.

Oh, and for the meters (I happen to have a bunch of them already here in the shop) :

Amazon

https://www.amazon.com/HOME-DECOR-DT830B-Multimeter-19-Range/dp/B001T3Y8XW/ref=sr_1_fkmr0_2?ie=UTF8&qid=1516153368&sr=8-2-fkmr0&keywords=miyako+dt-830b

Hello folks,

No case made yet, so it’s still in my amplifier chassis jig. But it works sweet!

Here’s my implementation of the instrument:

http://i112.photobucket.com/albums/n197/cberkeley/Tube%20Tester_zpseiggdv9a.jpg

Thanks for a very useful device and a great project!

Hi Grant,

I’m assembling the parts to build your tube tester. I was planning on using a 12vct filament transformer so I can test both 12V and 6V tubes.

Thinking about using a 7809 regulator off the 12V transformer to power the meters. You mentioned they need to have separate power supplies because of different ground pontentials. Can I do what I want by simply using one regulator for each meter?

Hi Jon, good to hear of your plans. You can power the grid bias meter from a ground referenced power source, but the plate current meter floats at HT potential meaning that the power to it needs to be isolated. One builder of my tester took the approach of adding a DPDT toggle switch to turn the meters on and off. You may want to do the same. Cheers, Grant

Good idea!

Thanks!

I would like to build your valve tester but like more of the people who replied to you I have drawn a blank with the transformer.I have got various transformers from old radios but 2 amps.could be a problem. Maybe someone reading this might be able to advise me on a substitute. Regards Dick

Hi Dick, depending on your country there are suitable transformers that can be substituted. What you need to locate are a 6.3V@2A and a 30V@2A centre tapped transformers. Alternatively substitute the 30V centre-tapped transformer with two 15V@2A transformers with the two 15V windings in series. If you look back through the comments above, there are several suggestions for alternative transformers. Trust you locate suitable transformers – it certainly is a useful tester!

Hi Grant,

Thanks for your great design.

Refering to the question of Jon Block, I was wandering if it is possible to take the current measurements from the kathode and not from the plate and getting the same results. Am I right in thinking this and that In this way the mA meter sees no high voltage so a simple ground referenced power supply for a digital meter is possible? Regards, Jaap Schijf

Hi Jaap, the valve current can be monitored from the cathode as you suggest, but this will mean you are measuring the sum of anode and screen currents when you are testing pentodes.

My approach requires monitoring current at a high voltage as you say, but assures an accurate measurement of anode current alone. Of course if you were only measuring triode valves, the cathode current is the same as anode current so your approach would work fine. Hope that helps!

Thanks for your answer. Very helpfull.

Regards, Jaap

Hi Grant,

Thank you for this excellent design! Like others, I had a lot of difficulty sourcing the 30vCT or even 2 15 volt transformers at 2A in the U.S. and finally found one! Here’s the link:

https://www.maddison.ca/adaptateur-transfo/entree-ac-sortie-ac/mad-005787.html

They’re in Canada, and unfortunately do not have shipping to US enabled for web orders, but you can give them a call (if you speak french) or send a google translated email to request a purchase with shipping to US, it’s worth a try, it worked for me. The 30vCT is about $10US and shipping would be about $20US, not the cheapest overall but after searching for any suitable combo of 30vCT or 2 of the 15v at 2A I was just glad to find one somewhere, anywhere!

I just thought I would share since it finally arrived and I’ve confirmed that it has the advertised output.

Hope this helps others that are searching for this elusive part in the U.S.

Thanks again to Grant for the excellent design!

Cheers

Hi Steve,

Thanks very much for the update on sourcing an alternative transformer. Cheers!

For those wishing to use the mini-multimeter Grant sourced from Jaycar (QM1502) they don’t seem to stock them now (2018). Of course, the answer is Ebay. – and I found this item which appears almost identical.

https://www.ebay.com/itm/Mini-LCD-Digital-Voltmeter-Ohm-Multimeter-AC-DC-Voltage-Multi-Tester-Meter/332168009569?hash=item4d56c19761%3Am%3Am30BiVShL9JAprbPH9hl29w&var=541202875604

Thanks Ross for the heads up. Yes, just about any cheap multimeters will work in my tester.

Hi Grant

Just some newbie questions about the ground connections. Are we using the baking tray as the ground plane? I suppose the earth wire of the power cord is also connected to the baking tray, correct?

Cheers

WT

Hi WT, yes the baking tray is earthed for safety. Cheers

Dear Grant, I have sourced almost all part for the valve tester and looking closely at the photo of the power board I noticed that there are two resistors of 220k in parallel; supposedly R7 for the simple version and R5 for the full version. But I also noticed a 100k resistor in parallel with a 470uF 200V capacitor (C7 in the simple version and C6 in the full version). I can’t seem to find the resistor in either schematics, so my question is: Is this resistor necessary?

Hi Willem, great to hear you are building the valve tester. To explain the extra two “bleeder” resistors on the power supply board, they were added early in the build but are not necessary – a single resistor of any value around 150K to 220K is all that is needed. Its purpose is to discharge the power supply capacitors when the unit is turned off. Hope that helps!

Instead of these bleeder resistors can I use and on-off-on power switch with the second “on” switch being “discharge”? “on-off-discharge” for the power switch positions.

Hi Rick, it is not a good idea to short charged electrolytic capacitors as the large discharge current can damage them. Bleeder resistors are a kinder way to discharge a capacitor as the discharge is slower. Cheers

Hi, just how high can you go on the center tappet transformer?

I have some 18-0-18 toroids collecting dust.

Best regards

Hi Rick,

The 18-0-18V transformer would increase your test voltages by 20% – that could be ok if you take it into consideration.

Hi Grant,

I found two transformers on RS Components. May be these are useful for those who are still looking for the transformers.

6.3V dual secondary RS Part No: 504-561

https://docs-apac.rs-online.com/webdocs/15c2/0900766b815c22dd.pdf

15V dual secondary RS Part No: 504-022

https://docs-apac.rs-online.com/webdocs/15c2/0900766b815c22e8.pdf

Just one more question regarding the wiring of the transformers. Does the diagram below look correct? Does it matter if we use 0v lead or the 6.3v lead as the ground for the filament transformer?

https://www.flickr.com/photos/49608673@N02/42069659540/in/dateposted-public/

Thanks again!

WT

Hi and thanks for the link to the RS transformers. They would be viable options for my valve tester. The diagram you linked is fine and it does not matter if you ground a “0V” or “6.3V” lead – those voltages are just relative to each other.

Hello Grant,

I just discovered your design (I’m new to the tube world, but experienced with electronics). I will certainly be building your tester! I have two questions (for now )

1. Neon tube: should it be 240VAC or can I substitute 120 VAC?

2. I would like to use the digital panel meters like this: https://www.ebay.com/itm/DC-200mA-Red-LED-Digital-AMP-Ammeter-Panel-Digit-Current-Meter-0-200mA-DC/110956423447?hash=item19d584a917%3Ag%3AU3MAAOSwOeVZzl-y&_sacat=0&_nkw=Digital+panel+meter+0-200ma&_from=R40&rt=nc&_trksid=m570.l1313&LH_TitleDesc=0

Should I use 0-100mA (to be more accurate?) and voltage Meter 0- 200VAC ? Or 0- 400VAC?

Thank you for making this project.

p.s. I will be testing only the 12AX7, 12AU7, KT88 and possibly 5AR4 (last one is a rectifier tube so I’m not sure if I need a separate tester/configuration).

Thanks again!

Regards,

Paul J

Hi Paul, ideally you should use a 240V neon, but if you have a 110V neon, just add a 220K resistor in series with it.

Regarding the panel meter you suggest, it requires an isolated power supply for each unit and the LED display draws a significant amount of current. That is why I used multimeters that have low current drain and battery supply to isolate them from the high voltage. Cheers.

Thank You for your fast answer – I’m collecting parts now 🙂

Hi Grant,

Thank you so much for the wise design. I love simple and effective designs! it can be easily modified if one wants more features/adaptations.

Cheers.

Aviv from Israel

Hi Grant,

Is there any disadvantage in using a toroidal transformer?

Thanks,

Aviv.

Hi Aviv,

A toroidal transformer or two with the appropriate voltages would be fine for the tester. Cheers.

Hi

Thanks for the project. I was looking at version 1 and only want to use it with 12a*7 tubes. I assume i can eliminate the other sockets and high switches? Anything else i should consider?

Thanks

Hi Jason, thanks for your interest in the valve tester. Yes, the circuit can be simplified if you are only testing 12AX7 type valves. You can also scale down the power supply as it only needs to provide a few mA of current

hello,

how are the DMMs attached to the case? also how are the DMM leads connected or did you solder wire to the sockets?

thanks

I used silicon sealant to fix the DMMs to the case. Yes, I soldered leads directly to the pcb inside the DMM.

brilliant! thx

would adding rcas for signal in and signal out make sense if i wanted to add a freq generator and scope for noise testing?

Hi Jason, in theory this could be done – see my comments above. Cheers.

Hi Grant

Thanks so much, I am based in UK and desperately in need of a valve tester but could not afford one, so this is a gift. I have trawled Q & A’s above but being a newby to more complex electronic projects (sorry if being daft).

Main valves I have to test are 6AS7G – heater pulls 2.5 amps at 6.3 V . So you guessed it Transformer advice AGAIN!!!!! (sorry)

The 2 X RS Tranformers above I assume both are needed (one for heaters one for test supply) making it more pricy? + might be blind but cannot find amp load for them.

I have found this at Jaycar

https://www.jaycar.co.uk/12v-30v-100va-6a-multi-tapped-dual-type-2170-transformer/p/MM2015

Would this be any good? would I have to change anything in your circuit to use it? I tried the Jaycar linked to previously but does not come up!!!

For me this Jaycar if OK would be great as rated at 6 amps and if poss I want to test 6336A/B with heaters at 5amps.

Hi, there might be a few challenges to test low mu triodes like 6AS7 or 6336 with my tester. As you identify, the heater transformer would need to be upgraded for the higher heater current. The other issue is that these triodes need a high value of bias: up to -60 or -70 volts. My tester generates a maximum bias voltage of around -43V and would need to be redesigned to provide the higher amount of bias.

Hi Grant

Thanks for that.

Hmmmm! This might be an issue as 6AS7G is the main valve for me to test. Heaters possibly not so much of an issue as can presuably run a sperate transformer for them. However the bias control? Any idears on how much work to adjust your circuit to accomdate this valves needs? (forget 6336 as I believe even more extreme). Advice on this might help many out there as the 6AS7G is the most common OTL amp valve and they use a lot of them. Here is the data I have on it.

Heaters 6.3 V at 2.5 Amps

–Plate supply 135 Volts

Cathode-bias resistor 250 Ohms

Plate resistance 280 Ohms

plate current 125ma

MAXIMUM RATINGS

Plate voltage 250V max

Plate current 125 mA

Plate dissipation 13 Watts

Peak Heater-cathode voltages Heater neg and Pos with respect to cathode BOTH 300 volts Max

MAX CIRCUIT VALUES

Grid-circuit Res — Cathode— bias operation 1.0 megohm Max. Fixed bias operation NO

Could you also advise on 6SN7GT

Thanks again Grant for your efforts and time for us Valve nutters your passion for valves must be great.

JO

Apologies me again. Trawled through above again to discover nobody seems to of asked so may be I am being incredibly thick but are all the caps polar? non Polar or a mix? If so which are which or does it not matter?

Sorry if ive missed something or being a complete nonse.

JO

ohhh! and thanks again

Hi Jo, yes all of the capacitors except C1 (a 100nf) are polarised electrolytic capacitors.

Hi Grant Ive been studying circuit in an attempt to resolve issues with adding to its capabilities to test 6AS7G. Identified Issues — Heater current, High Bias value and need for higher Voltage supply to plate which I believe is 300V (the 3 issues identified so far, hopefully all of them?)

Separate Transformer to supply Heater part of circuit, say an arbitrary 6 A at 6.3 Volts

New values for C3 (47 uf 63V) and VR1 10K pot.

Add on one more section to the voltage multiplying ladder and adding switching to accommodate its use (possibly a 4 pole switch).

So my question is would this work? would it interfere with any other parts of the circuit or valves it can test? any issues or precautions needed in implementing these adaptions?

Finally and cheekily Is it possible you would be able to work out the values needed to the above components that are needed to expand this great bit of kits capabilities to cover this family of mu triodes. I understand if not and can hopefully find someone here to help me.

All best JO

Hi Jo,

Yes in principle the changes you suggest are in the ball park. However, as you probably are aware, there is a fair bit of time and bench testing involved in taking the idea to a successful implementation so sorry can’t assist.

Hi Grant, I’m considering building your tubes tester, thank you for making the plans available and sharing the knowledge you have gained.

I am considering making a few changes to get higher plate voltages so I can not only test but match tubes for guitar amps at closer to their actually operating parameters in that situation. I already have a suitable 48V transformer and I am thinking this would give a 62.5% increase to the voltages. I’d of course have to up the cap ratings and likely larger bias pot for more adjustment. But, do you foresee any other challenges as far as just scaling up the voltages?

(As a note: I will be using a separate 6.3V filament supply)

Also, in your experience, would their be any benefit to the higher output voltage in terms of matching tubes? Can you get consistent matching results at these lower voltages that also translate to the more punishing environment of guitar tube amps?

Thanks!

Hi Jason, good to hear you are planning to build my tester. In theory, your suggestion to boost the test voltage would be fine – you would need to increase the voltage ratings of the power capacitors and as you say increase the bias voltage as well.

With regards to matching at different supply voltages, a pair matched at 250V will be in the same ball park when operating at a higher voltage, but I would suspect there will be a small difference.

Very interesting project. I want to test most common tube types used in guitar amps which I service.

I’m also starting to service old Jukebox amplifiers, some of which use Direct Heated Triodes such as 30’s 45’s etc. Would like to be able to test 2A3’s and 300Bs too. Can this tester be easily adapted to test Direct Heated Triodes? Am I better off having a separate tester for those types? Thanks

Hi Larry, in principle directly heated valves can be tested with my design – you just need to provide the correct filament voltage for these valves making sure that one side of the filament is grounded.

Thanks Grant!

I’m starting to look around for parts to build this tester. I have a couple other questions.

I see you mentioned life test. What would that test consist of?

What is the maximum grid voltage this will supply as it is? I imagine it could be increased, if needed, with a voltage doubler as you do with the plate/screen voltages? I’m thinking a 45 and a 300B may need more grid voltage?

Can your tester work for rectifier tubes?

Thanks again!

Hi Larry,

A “life test”consists of running the heater at a reduced voltage (one volt or so) and seeing if the emission drops substantially. A good valve won’t drop in emission much with this reduction in heater voltage.

Yes, the grid bias voltage as it stands is a maximum of approx -45V. This voltage could be increased with a voltage doubler configuration.

My tester does not provide for testing of rectifier valves.

Hi Grant,

Firstly many thanks for sharing your design, I have subsequently built one and find it very useful.

In my quest to better understand and enhance my testing capabilities, I notice that there is no current inclusion for an Anode/Plate load resistor (RL), whereas I have read that for some calculation purposes then RL value is required. Any suggestions for a value to use that could meet perhaps 12AX7 and KT88 in testing?

Please feel free to correct me if I am missing something.

One more question … do you have forum to post pictures of your design?

Regards

Hi Janus,

Thanks for your comments. With regards to anode load (RL) values, they are relevant when designing the appropriate anode load for a preamp or power amp design. The valve is driven with signal, and an ac voltage is then impressed across this load. However, when testing valves for emission, Gm, gas etc, no anode load is required and in fact any additional anode resistance will compromise these tests. Hope that helps.

Regards a “forum to post pictures of your design” I assume you mean for builders of my projects to post pictures of their builds. I don’t have this feature in WordPress, but I may look into it in the future. Cheers!

Dear Sir, I am seriously considering building this to test tubes on old 30’s and 40’s radios. From my readings and understanding this is mainly for the newer tubes in amps and such, correct? I am curious if you think this would be suitable for my tubes and thank you for your build and your time.

Hi Eric, thanks for your enquiry. My tester will test older receiving valves fine, you just need to provide suitable sockets for the valves you wish to test.

Hello Grant.Nice project.Please tell me,can i test ECF80 tube? Thanks.

Hi, yes you can test an ECF80 if you build the extended version of my tester with the ability to apply the test voltages to individual valve elements.

Hiy,thanks for the reply.

Where do I get it the extendet version?

I want to build it,Thanks.

Hello Grant!Can you help me?Thanks.

The extended version of my tester is included in the pdf. Regards, Grant

Hi

This is a fantastic project. With respect to the https://uk.rs-online.com/web/p/products/0504561/ 6.3V-0V 10VA x 2 transformer mentioned above, do both 6.3V windings need to be together to supply the appropriate current since one winding is only coming in at 1.6A, or how would that work?

Hi AJ, a single 6.3V 1.6A transformer would be fine for any valve up to an EL34, but if you are testing valves with higher current ratings, you can use two with paralleled secondaries.

Hi Grant

I’ve just finished building the first version of DIY tube tester into a Hammond case and it works really well. I am in the UK so had to use different transformers but got there in the end. If you’d like a few photos for your website drop me an email. Thanks Rob

Hi Rob, great to hear you have built your tester successfully. I’ve emailed you re the photos. Cheers

Hi Grant,

I just wanted to thank you for your neat project!

Fired it up for the first time today with no issues. It’s a great design, and I copied your build closely with local parts here in NZ. I’m really looking forward to learning more about valve testing, and this will be a great learning tool. (I already have a box of old Radio Valves to test for upcoming projects!)

Thanks again for sharing your project!

Kind regards,

Corey

Christchurch,

New Zealand

(Pics in the link)

Hi Corey, thanks for the link to your valve tester build – well done!

Grant

Hello Grant,

I have just come across your valve tester and am gathering the components required. I have one query though. You show grid and screen stoppers in the “simple” build but none in the full version. Are they required for the full version. Thanks for a fine project.

Phil

Hi Phil, great to hear you are building the valve tester. Re the “stoppers” – they are hard wired in the simpler design because the grid and screen pins of the valves are known. In the full version however, the screen and grid pins vary depending on the particular valve type being tested and so R1 and R2 are added as the stopper resistors. Hope that helps!

Hi Grant,

Thanks for your reply and and for clearing up my query. I look forward to being able to test the valves I am going to use for a couple of builds I have in the pipeline.

Phil

Hi,

Why a Neon indicator? Wouldn’t an LED work as well?

Thanks.

Hi Kevin, a LED is not suitable for this application due to the current which it requires. A neon is the ideal device to interface with the high voltages involved in the tester. Hope that helps, Grant

Grant, something else I wanted to ask you . . . in your write-up on how to build/use the tester you mention using 4N28 Optocouplers, but in the schematic you have 4N25 Optocouplers. I ordered 4N25 Optocouplers, but they sent me 4N35 Optocouplers by mistake. Will the 4N35s work just as well?

Thanks again.

Hi Kevin, Any of the 4NXX family will be fine – they are used in a very basic switching function in my tester and any opto will be fine. HTH!

Hi Grant,

I’m new to tube testing theory, so forgive me if my question is too basic.

I have a lot of arduino related stuff, including a precision current meter (based on a INA219 IC) but it needs a voltage bus up to 26V so it does not burn down. Is the plate current being measured on the high side of the tube or am I reading the schematics wrong?

If I’m right, this way the voltage bus would be up to 250v, right?

My idea would be to use an arduino to measure and compute the information, with a display associated.

Thank you.

Hi, yes you are correct – the plate current is measured at the plate at high voltage. If any other method is used to measure current, it will need to float at high voltage. Hope that helps.

Grant, thanks for the reply.

I guess then I’ll set this arduino idea aside. Let me ask you another thing: I already have 2 good DMMs that I use to bias my amp among other things and I’d like to use them in your tube tester final version as well, but with an external interface… I thought about using 2 sets of banana jacks as inputs and plug the DMMs when needed with the additional benefit of using a smaller enclosure for the tester.

I would remove the whole branch of optocouplers & 9v batteries cause it would no longer be needed but how can I ensure 6.3v to the heater H jack? I would stil be able to get this voltage leaving D1, C2 and R4, moving the GND right after R4? I believe I would need to change R4 value, but I can’t figure out the new value. Thanks!

Hi, yes you can substitute your existing multimeters to measure grid voltage and plate current.

Hello I have a pair of 25L6GT and I dĺike how I can supply it from 30+30V transformer. I thinked to use one side of 30V for the heathers of 25L6 in series with 12AX7. The transformer have center tap, and gives a current around 3A.

Hi Pedro, yes you need to be a bit creative to test valves with heater voltages that differ from the normal 6.3V. Ideally for your 25L6 valves a transformer with a 25V secondary would be required. Another possibility is to feed the heater of the 25L6 being tested from a bench power supply set up for 25V DC. Hope that helps, Grant

HI great looking project (im late getting into this publication)

just before I wire everything together , the electronics wiz at work has seen the schematic and forced me to stop and clarify why the 30 v out on transformer is going to ground and 24v for the 6 v line are connected like they are.

Hi Kev, thanks for your interest in my valve tester. Re the “30V going to ground”, the taps on a transformer are arbitarily designated. if The “30V” tap is grounded, then the “0V” tap becomes 30V, the “24V” tap becomes 6V and so on. The transformer was wired this way to allow for a 6V tap on the transformer to feed the valve heaters. Hope that assists!

Hi Grant bit late getting back to this project (nearly 2 years) other things get in the way.

I must just touch the subject of the switches , i know previous people have asked about them but im still confused on the DPDT as far as i understand it you have used it as a SPDT to increase is load bearing my confusion is the picture seems to show 2 wires coming of one end where i would have expected just one each end , could you please clarify.

Hi Kevin, yes I used a DPDT switch with each section paralleled up. There are 2 wires from one end but they are the same connection as the two sections are joined. HTH

Hi Grant, is there anyway that an addition to the schematic could be added to test the UL range of valves.

Hi Dick, yes my tester can be expanded to test any valve – you need to provide a suitable socket and a source of suitable heater voltage. Cheers.

Hello!

Let me say that I also managed to assemble this tester. The problem, however, is how and what to measure. Is there any manual or maybe anyone has some data and instructions to measure with this tester? Could anyone please make and post instructions on how to measure and use this tester? Yes, we are not all electronics engineers. I’m a fan of guitar amplifiers and would love to test tubes myself. And btw, why are there no pictures posted of testers anywhere from the ones who made this tester ???

Thank you and Happy New Year

Josko

Hi Joe, great to hear you have built this tester. To use it, you need to refer to tube datasheets from Google for the particular tube/valve you wish to test. There you will find reference to “typical operating conditions” where suitable plate, screen and grid voltages for the particular tube are referenced. You set up those voltages on your tester and read the plate current. For measuring GM, vary the grid voltage by 1 volt and note the change in plate current in mA. This reading in mA/V is the tube GM. Trying out a number of tubes helps you become familiar with this process. Hope this helps, Grant

Hi Grant,

I understand how to test GM but what about emissions readings? How do you conduct this test or is it really necessary once you have GM?

Thanks!

Erik

Hi Erik, emission tests are are at the heart of the what this tester measures – apply datasheet voltages to plate, grid and screen (for pentodes) and the emission is read directly from the plate current meter.

Grant, I built your tester. It is fantastic!

I’m in the US so I ended up using a 17-0-17 transformer. I have the tester on a variac to dial in voltage at the plate. Correct me if I’m wrong but I believe I can calculate the tube Mu (amplification factor) by using the variac to vary the plate voltage vs the grid voltage using the bias adjustment to hold the plate current constant. Mu = delta Vp / delta Vg

Is this right? Very useful for stereo preamp tubes.

Hi Grant,

Thanks a lot for those awesome designs! I built the simple one to check only audio tubes. This said I would like to confirm something. Turning the pot, I get a grid voltage variation from 0 to -41 volts but this also induce a high voltage variation from 150 to 250 volts measured across R7 (150k). Is that normal ? I double check all the wiring and tests all parts and everything seems to be fine. I though the High voltage should be stable to 125 or 250 volts depending of the switchs settings. Also the neon never turn on as a power indicator when the tube is conducting. I measured around 1 volt max across the neon connections. May be you or anybody with the answer can give me a cue … or suggestions where can be my mistake… That will be really appreciate ! Thanks !!!

Hi Jay,

The HT voltage should not vary very much as the load (the valve) draws more current. It sounds to me as though you have an error in the power supply wiring. Or one of the capacitors in the multiplier has a high ESR value. Are you using the same values of capacitor as in the schematic? However the most likely issue is that your transformer feeding the multiplier is under rated. You need at least a 2A rating for this circuit. Cheers

Hi Grant, I tried another transformer: 28 volts C.T. 4 amps. I got a maximum DC high voltage of 225v because of the lower secondary voltage. Turning the pot I got a variation on the high voltage side from 200v to 225 volts. A lot better than before but still a 25 volts variation. You wrote that it should not vary much… can you give me some numbers as a reference ? The capacitors are all brand new 470uF as the schematic but with higher voltages rating (200-300-450 volts). I did not checked the ESR yet… but will do as soon as I can. Note that I’m in North America so the primary is at 120 volts. Also I use a separate variable DC power supply for the filament adjusted precisely at 6.3 volts. I did not connect the (-) of this DC 6.3 volts filament to the ground of the tester… Thanks for your help Grant !!

Hi Grant

Great job! in the next weeks i’m going to build your tube tester.

I’ve read all the comments in order to fit everything.

I’m going for the two transformers version, bytheway, locally i cant find nothing, so i have to buy from US and then pay a separate shipping fee in order to get them to me.

My “problem” is: weight=expensive shipping fees.

So i decided to use a 6v 3A dc power supply for the heater’s(cheap and light), for the 30v ct transformer can i use a 30VA one, or i’ve to stick with the 60VA?, and for the meters if i want to eliminate the digital one can i go for something like that:

the 200V dc https://www.ebay.com/itm/1PC-DC-0-200V-Round-Analog-Voltmeter-Voltage-Panel-Meter-Dia-90mm-Plastic/173146045324?_trkparms=ispr%3D1&hash=item28504efb8c:g:mHkAAOSwNMVaerjF&enc=AQAEAAACUBPxNw%2BVj6nta7CKEs3N0qUryD15bnK17Poyctcs%2B9b4hV7yySSHCWqCoVCJ%2F7yRf5Dj9Pz49PosJQ5SwDMLdjPTOMJwJpx4XBQ0xlkfdLE4d3VNOPJIquCCQSGnb4nIl3mSvC819lkq8WHrftqz7UfC8%2BCiEObr%2BkeACxIfkq%2Bp5ohzUyeDTqEqE%2Fd3iphkTbPxv99WinYs8kBgVJKLN4%2FcNk39bYW%2Bm98WbGOokpw4Y%2B820tBgYeBremewHK9v7H3fmRHbEAx57zAGTuRsFGY2b433AKDpy7WEJGB1hhB330Sou%2BywelxObhkt0HGiVDR1kgQsdu4c%2FpBc7d5vElXU5Gp8hAXOUqtd2iomQCjtPwPcWBXfLeNz%2FdH5XMXelwVxbKmP62%2B93ySu1MSfWJvF2Q1lvxqyLgfReNjUfvGhx9MOS4VSROUMc2zazfO6PIIU%2BZbYSAMZT%2FTGJ8RtsQJNDo6%2FmbH1pJWnFASAMqDT78FnM%2FJq3ZP2r66K%2B3NyncO%2BNvy2ELcsG5lrc9kK9%2FsNi6Cn4YXQ%2FkzkzJU6Wcts%2BXrGR0J2JbJXi6n19gD890PyrapeRq%2FVj3s%2FJ3xWiz3tWUCdXCcmQhTXTru8KRETHdcJYVq2HsxycSIXMcP%2FIoNcyR9BzUYi%2BPsZvRqKhJFCSUUPWI0K6TS5PkN7HWZkk11GIYzK7JOzq6rxcYzSSukLPXejq5J9vluFPjmhe5pioBAcKodLFSndJvK0z%2B9B%2FGNdkF5xm%2BpHwpgxehnutHsecGf7Y%2BctLXKpmUuj7P8%3D&checksum=173146045324f5c79b044ce74cdea1ac8c262e81a2fe.

and the 200mA one: https://www.ebay.com/itm/DC-0-200mA-Round-Analog-Ammeter-Panel-AMP-Current-Meter-Dia-90mm-Direct-Connect/181714909210?hash=item2a4f0d781a:g:Qm8AAOSwvc1ZZd7W.

What are your suggestions or correct me if i’m thincking wrong.

Thanks

Hi Mike, yes the meters you suggest are fine but lack resolution over the whole range. That is why I used digital meters. Cheers, Grant

Hello,Can it be used with this transformer ?

https://toei-trans.jp/?pid=91217141

Hi, yes that transformer would be ideal for anyone building my valve tester in the US or Japan with 110V supply. Cheers, Grant

Doumo Arigatou !

Hi Grant,

Thank you for your schematic.

I’m almost done assembling, just wanted to ask if is it normal that without load (tube) I obtain max 125V DC? Or should I recheck the rectifier assembly?

Mike

Hi Mike, no the 125V DC is not what you should be seeing at the output of the power supply. I suggest you check your wiring in the voltage multiplier section. Cheers, Grant

Hi Grant,

First of all, thanks for this really handy tube tester design. I can see that it’s been exactly five years now since you set up this project, but it’s never too late for such a good one. I’m pretty green on tube electronics, but still “relatively” easy to get around to the scheme, except for the C3 electrolytic capacitor which is connected to the ground line with a positive pin. I would ask you to explain purpose of such a connection.

Thanks in advance.

Hi Nenad, great to hear you plan to build my tester. The reason C3 appears to be “backwards” is that it is part of the negative bias voltage network and so the positive leg of the capacitor is grounded. Hope that helps!

Hi Grant, thank you for your answer, now everything ok with the power supply…

It works smoothly… Until I put the tube on… Then I can’t read the voltages on tube pins with my multimeter, it shows everything zero… The small multimeters write as an example with -2V grid an anodic current of 180mA, really too much, where with this tube (pentode Chinese 6J1) I had expected 20/30 mA… I can’t find out the issue here, what’s your take on it?

Thanks, Mike

Hi Mike, good to hear you sorted the power supply wiring. It sounds like you have other wiring issues as well – my suggestion is to print a fresh schematic and check every connection in your build is as per the schematic. Once you are sure each lead/wiring is correct mark its lead on the schematic with a marker pen. That way you confirm that it has been wired correctly. Regards, Grant

Yes, sorry, I had the second filament brought to ground… Now everything working properly! You can also delete this and previous comment, thanks!

Hello Grant!

I don’t have a high level of electrical knowledge, but I am very happy to be able to get a circuit diagram from you that I find very useful in managing my equipment.

Now I am collecting parts, but there is one thing that I am curious about.

Can I use a 240v filament bulb instead of a 240v neon lamp? If possible, are they used with resistors?

Also, is it okay to ask more questions when you have trouble making a tester?

(p.s: It is difficult to express because I am writing through a translator. If you feel impolite, please forgive me, I am not sincere.)

Hi, good to hear of your interest in my valve tester. The unit does require a neon lamp – they are available as a panel lamp assembly from most parts suppliers.

Ah-ha! Okay,I see.

Thank you for your kind answer.

Your work will also play a very nice role in my work in the future. Thank you.

Hi Grant,

I love your tube tester design and am in the process of researching parts, but I’d like my tester to be able to check tubes of the 1920s (45, 47, 27, 80, etc.), so I’ll need 5V and 2.5V supplies for those filaments.

I’m in the US and have found what I think is a serviceable plate/screen transformer (Hammond 28V, 2A, CT*), and there’s a cheap 6.3V, 2A filament transformer that Hammond makes, as well, but I’d like to avoid spending another $40 on separate 2.5 and 5V transformers if at all possible. Can I rig up a switch with some wire-wound resistors to toggle between the desired filament voltages? Forgive me in advance as I know my electrical theory is lacking…

Thanks!

*I assume that 2 volts short of what your design calls for is OK? I have been unable to find ANY xformer with both 30V and 2A.

Hi Jonathan, yes my tester can test valves with different heater requirements – the best idea is to use a multitapped transformer look for something like this https://www.jaycar.com.au/6-3-15v-15va-1a-multi-tapped-type-2155/p/MM2002. You can select a whole range of voltages – for example between the 15V and 12.6V you have 2.5V…….. And your 28V transformer would work fine.

Thanks again, Grant. Separate xformers would allow me to use one for the plates/screens/grids rated for much lower current, no? Perhaps 0.5A? That right there would save nearly $20 USD. Then my filament xformer would have to be around 3A to handle the 80 rectifier, I suspect…

https://www.tubesandmore.com/sites/default/files/associated_files/p-t166g28_specification_sheet.pdf

Hi Jonathan,

The transformer for the HT needs to be rated at at least 2A for good regulation of the HT. Regards Grant

Hi Grant,

I found your project for the tube tester, great design however the challenge here(Ireland) is getting the transformer. It looks like I’ll have to go with a two transformer solution. First for the heaters: 230V to 2 X 6.3V (20VA each), if I put them together in parallel will I get 3.2A in total for heaters? The second transformer for the HT is; 230V to 2 X 15V (25VA each) so I have 1.66A for the 15V choice and 3.33A for the 30V selection.

Am I correct in my assumptions?

I look forward to building this project and welcome your input.

Thanks,

Tristan

Hi Tristan,

Yes the two transformer solution you suggest would work fine.

Hi Grant,

Thanks for that. I have all the component on order and will hit the kitchen for a baking tray! I look forward to building and testing tubes. Regards, Tristan

Hello Grant,

I’m Pino, from italy.

let me said thank you very much for your idea about the tube tester, it gets me inspired to make my own tube tester with many of recovered stuffs I have in my workshop.

Unfortunatly, i don’t have a proper metal box, and i have used an “open layout” to make it.

Based on your schematic, I’ve added some small modification, like an adjustable HV from 0 – 300volt and a filament adjustable power supply too.

You can see some pic on the italian forum

stay safe, best regards

pino

Hi Pino, great to hear my design has inspired you to build your own tester. Cheers, Grant

Hi Pino, have you a link to your build? I’d like to see how you’ve done the adjustable HT. Regards, Tristan

Hi Tristan,

here you will find the description of my tube tester

https://elettronialtramonto.forumfree.it/?t=77536351

For the HT adjustable schematic, I’ve loaded it on:

https://drive.google.com/file/d/1Nw4wtwS7h4xl2wSLFqKIKTEs3Z6zGNMG/view?usp=sharing

Hi Grant

Thank for the design, looks brilliant

I’m just sorting the parts for the build, but I’ve just one question.

I’ll be using it mainly for EL84 and 34s, so was looking to do the basic version.

But I also use some 6N3P/5670 valves.

Would the basic version be able to test these, or would I need to build the full version.

Many thanks

Jack

Hi Jack, the basic version would be fine for other twin triode valves like 6N2, 6N3, 6DJ8, ECC88 etc. You would just have to provide switching for the different heater arrangement to a 12AX7 family of valves.

Hi Grant,

as you know, with your tube tester you cannot reading the Gm and mu of the tube under test, but you can easly calculate it by some formula.

I’ve arranged an Excel sheet for indirect calculation of Gm (Transconductance) and mu(Gain), which can help to understand if the tube is still in good condition. If you are interested I can give you.

Hi Pino, thanks – the spreadsheet would be very useful for anyone building the tester.

Hi Grant, let me to finish to localize it in english, then I’ll pubblish.

Hello Grant,

The english version seems works fine!

pls let me know your impression and comments

download it :

https://drive.google.com/file/d/1jDbY4uB6vXsVafeSEGV17T1X9YwdVMD4/view?usp=sharing

Thanks Pino for that!

Hello grant.

It’s finally finished, a very large sense of achievement makes me feel good, thank you again.

I made it in an early version format.

The transformers were 0-6.3v 2A, 0-15v-30v 0.5A, and they were made by experts and installed.

I tested EL34, 5881, 6550, and 12AX7.

However, some strange situations occurred.

1.Bias voltage is only displayed from 0v to -39v (this is large

I don’t think it’s a problem, right?)

2. For all power tubes, before the bias indicated in the tube data sheet

The plate current is only about 60% of the pressure (the tube is

These guys have been sleeping for 7 years in the packaging box.)

3. If the test is done 4 or 5 times, the 500ma fuse will burn out.

fuse capacity equal to power tube heater power (1.5A or 2A)

Can I upload it?

P.S: All grounds and 0v meet at one point of the chassis. Maybe, this

Is it a problem?

Please guide me to anyone who sees this article on a bright road !!

Hi Kim, the bias supply will provide up to -40V or so. The lower reading for emission could be due to a power transformer with insufficient power rating. Re the fuse blowing, that may be due to shorts within the valve under test.

Thank you !!

Your kind answer helped me a lot.

I wish you protection from covid-19 and other bad things.

Hi Grant

I have a question with regards to multiple transformers.

I have four of them, one for the 15/30 volt for the HV and three others to supply different heater voltages through a multiple selector switch , with the common from the selector to one side of the heater. Can all four transformers secondary (one side) share a common ground with each other as I mounted all four on a aluminum plate .

Hi Shawn, what you propose should be fine. Cheers

Hi Grant. I’ve just finished building your tester and I’ve some questions about it. I’m from Brazil, and the tester was built using 2 transformers (15 0 15 2A and 6 0 6 2A). I’m getting a plate/screen voltage around 254 to 262 VDC on the highest settings, but when connecting a power tube like a KT88, that voltage drops to around 215VDC. I’ve read that when introducing a load into the voltage multiplier circuit a drop would occur, but I’m thinking that this drop is too big. What could I do to mitigate this?

Regarding the gas test, every power tube I tested (4 EL34, 4 KT88) showed a lot of plate current increase. The EL34s were old, but sounded ok. The KTs, on the other side, were brand new. Maybe the getters need a little more use to reduce this gas?

Thanks!

Hi, the no load voltages look good on your tester, however the voltage should not drop as much as you have experienced. Are your power caps new or pulls from a computer power supply? Perhaps you have a cap with high ESR? Re the gas tests, you should not see a significant increase in plate current. Perhaps soak test the valves with heaters activated for 12 hours or so – you should see the getter reduce the amount of residual gas in your valves. Cheers.

Thanks for the reply! All parts are new and bought from Mouser, except the transformers, resistors and hardware. The power caps are nichicon and epcos branded: LLS2V471MELC, B41858C9477M000 and B43501E2477M000.

Would changing the main transformer for a 3A rated one provide more stability?

Regarding the gassy valves, the EL34 were used for years, so maybe they are gassy and that’s it. The KT88 will be “soaked” and retested.

Hmmm…… perhaps your power transformer is not up to the task – check to see how much the 30V AC input to the multiplier drops when the HT is loaded.

Ok. Measured (True RMS) with the EL34:

Outlet 125VAC

Tester without load: power transformer output 32.77VAC, B+ 262.5VDC;

Tester with load: Power transformer output 29.57VAC, Grid -13VDC, B+ 216 VDC

A few more data:

The Plate current was around 50mA with the load on. Pressing the gas button made it increase to around 96mA and the transformer voltage dropped to 26.4VAC.

Grant, just another question: 470uF 350V capacitors are very hard to find in Brazil, I had to import the one I´m using, but 470uF 400V are very easy to find. Could I use the 400V one if the original goes bad?

Yes, the 400V capacitors are fine

Hi Grant. Super cool project! Thanks so much for posting it for everyone else’s benefit.

I’m in the US and could only get a 28v ct transformer for the plate/screen voltages (3A rating). It’s wound for 115v on the primary but we usually get about 120v on the mains, so I’m hoping this will work. I have some questions though.

1. Do you think it’ll work given the PT?

2. Can you provide some more details on usage? Maybe a simple example using a 6L6 or EL34 with references to the data sheet would be really helpful.

2a. Specifically, you mention that, after setting up the banana plugs for the given tube and setting the grid voltage to what the tube datasheet, you can read plate current on the DMM. But what next? To what datasheet figure do i compare my reading? And what does that tell me about the tube?

2b. You also mention changing the grid voltage by 1v and calculating the change in plate current to get a Gm (transconductance) reading. Again, what next? To what datasheet figure do i compare my reading? And what does that tell me about the tube?

Thanks in advance for the excellent design and any help/advice you can offer.

Ray

PS – Again, many thanks for the great design. I have a lot of tubes ive got over the years. Always wanted to be able to test them 🙂

Hi Ray, in answer to your questions, your transformer should be fine.

RE using the tester, the best strategy is to download a datasheet for the valve under test. It will give typical voltage and current readings for all the valve elements. By comparing the tester readings against the data sheet you can get an idea of the valve condition. The best way to get familiar with the tester is to just use it.

Hi Grant,

I am about to start building your valve tester, thanks for the design, it’s just what I need at present.

I am restoring my Grandfathers Kriesler 11-103 Master Multisonic that has been sitting dormant for over 30 years. Have replaced almost every component now due to necessity and faults. I thought it only appropriate to test the valves to give it its best chance at sounding brilliant again.

So, my only question regarding the tester. Is the (DPDT) toggle switch for the HI/LO volts that is directly after the transformer a center OFF or just a change over (Break-before-make)?

Hi Andrew, good to hear of your plans to build the tester. Yes, the switch is a break before make toggle not centre off. Cheers

Hi Grant,

Hope you are safe and well.

Took a while to get back to you. Thanks for clarifying the toggle switch.

One more question/s.

What is the highest current draw in the cct. Sourced everything, just wondering about the “hook-up” wire. Altronics 1.5A (26AWG / 7/0.16) be sufficient?

Can I test a 6CA4 rectifier valve? Looking at the valve spec sheet, doesn’t give me much I can relate too for setting up test conditions.

Thanks for all your work around this tester, much appreciated.

Hi Andrew, thanks for your kind comments. The highest current flowing in the tester is in the heater wiring – your 1.5A wire would be ok, but if you can source it 2-3A rated wire would be even better. Re the 6CA4, my tester is not set up to test rectifier valves like a 6CA4.

Thanks Grant.

Can hardly wait to finish this project, can send a photo when complete if you wish. I checked the voltages and outputs of the 6CA4 in cct with a CRO. Looks good enough so assuming all good.

Hi Andrew, just confirming that my tester cannot test rectifier valves. To do so without anything to limit the plate current could damage the valve and/or the tester. Regards, Grant

Hello friend, I’m about to build your valve tester, thank you for sharing.

In testing a new 12a * 7, the plate current is 1.2mA.

The voltage apply is 250V and the neon resistor 220K, the current in this resistor is 1.13mA. The amperimeter measures the current in the not counting the current of the neon resistor, but part of the current drained by the plate cannot be supplied by the neon circuit?

Best regards, Raphael.

Hi Raphael, thanks for your interest in the tester. The “shorts” neon is only in circuit when testing for shorts. It is not in circuit when testing for emission. Hope that helps, Grant

Thanks for the answer Grant.

Should I install a neon bypass switch? Or do the diodes do this job?

Or can I leave the neon connected during valve testing?

Hi Grant, Thank you for sharing your design for the valve tester. I am presently breadboarding the multiplier circuit and am using a 2 x 15V (20VA) transformer with the secondaries in series to provide my 30 V. I have a separate transformer for the heaters. With no load the voltage at the transformer is 37 V AC which produces DC values way higher than your design (300V DC). My question is 1) will testing a single valve (say a 12Ax7) be sufficient load to pull the DC voltages down to the correct levels? 2) if not, would it be sensible to remove a stage of the multiplier? or is there another way you could suggest to bring the DC values back into spec. I hope you can help Regards Ray Hopcraft

Hi Ray,